How Technology Is Transforming Global Trade

You need components from three different suppliers across two continents, and your production line starts next week. A decade ago, this scenario meant stress, overnight shipping fees, and hoping everything arrived on time. Now? You handle it from your desk in an afternoon.Â

Digital tools have changed how businesses buy and sell electronics globally. What used to take weeks of back-and-forth now happens in real time through platforms that connect buyers with suppliers anywhere in the world.Â

Platforms Put Suppliers at Your FingertipsÂ

Companies in electronics B2B work through digital systems that bring buyers and suppliers together in one place. You log in, check inventory from multiple vendors, compare prices, and place your order. Done.Â

Real-time tracking shows you exactly where your shipment is. Your container clears customs in Singapore? You get notified. Delay at the Port of Los Angeles? You know immediately and can shift your production schedule before problems multiply.Â

Smaller distributors now compete with major suppliers. A component shop in Shenzhen wins contracts from Frankfurt buyers just as easily as distributors with offices across Europe. Location stopped mattering when everyone got access to the same platforms. Your stock levels, delivery speed, and pricing determine who gets the business.Â

Electronic Documents Cut Transaction TimeÂ

International electronics shipments need bills of lading, customs declarations, certificates of origin, inspection reports, and insurance papers. Paper versions create bottlenecks at every step. Clerks verify signatures manually, forms disappear in transit, and shipments wait at ports for stamps.Â

Digitally deliverable services reached $4.5 trillion in global trade during 2023. Developing economies accounted for over a trillion dollars of that total as electronic documentation replaced paper processes in cross-border deals.Â

Let’s take an example of a Taiwanese chip producer shipping semiconductors to Mexico. Digital platforms process all required paperwork while the cargo is still in Asia. Mexican customs receives the electronic files, checks the details, and approves the shipment hours after it docks. Semiconductors arrive at production facilities on schedule rather than getting stuck in storage waiting for bureaucratic sign-offs.Â

Blockchain Stops Counterfeit ComponentsÂ

Counterfeit electronics cause real damage. Fake microcontrollers fail in automotive systems. Substandard capacitors malfunction in medical devices. These counterfeits move through several distributors before anyone catches them, and the damage gets done.Â

Blockchain creates tamper-proof records. A manufacturer produces processors, and the blockchain logs their origin, production facility, materials used, and test results. Each move to a different location creates a record showing who got the components, the exact time of transfer, and where they go next.Â

Counterfeit parts are easy to spot because they don’t have the full custody trail that authentic components carry. Manufacturers use this to verify expensive parts, and adoption spreads as customers demand proof of legitimacy.Â

AI Spots Problems EarlyÂ

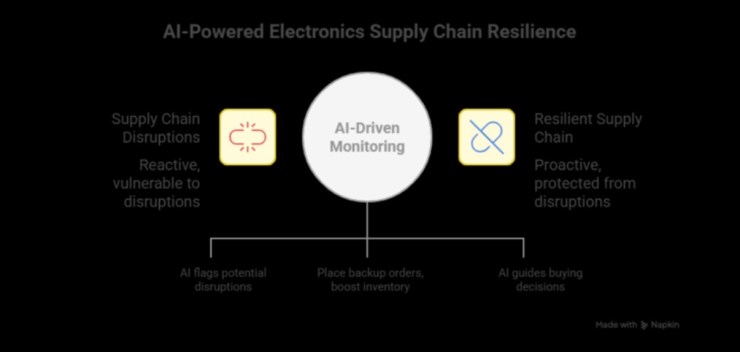

Artificial intelligence monitors worldwide factors that affect electronics supply chains. Storms threaten manufacturing plants, backed-up ports slow cargo movement, new policies block exports, and factories fall behind on output. AI flags all of it before disruptions reach your operations.Â

A typhoon approaches semiconductor facilities in Taiwan. AI sends alerts weeks ahead of impact. You place backup orders with suppliers in other regions, boost inventory buffers, or reschedule production runs. When the storm hits and shuts down factories, your supply chain stays protected.Â

The demand for AI technology has reshaped the global electronics trade. AI-related goods drove nearly half of global trade expansion in the first half of 2025, with trade in semiconductors, servers, and telecommunications equipment rising 20% year-on-year, while digitally delivered services are expected to grow 6.1% in 2025.Â

Machine learning pulls data from your past orders, what’s happening in markets right now, and projected future needs to guide your buying decisions. The software spots trends people miss. Certain vendors consistently deliver late during particular months. Component prices jump after specific trade shows. Your demand for particular parts follows predictable cycles. Â

AI uses these insights to suggest when you should order, which suppliers to choose, and how much inventory to keep.Â

IoT Sensors Monitor ShipmentsÂ

Temperature-sensitive electronics components need careful handling during transport. A container of semiconductors exposed to extreme heat or humidity becomes worthless before it reaches your facility.Â

Internet of Things sensors attach to shipping containers and monitor temperature, humidity, shock, and other factors throughout the journey. Conditions move outside acceptable ranges? The system alerts you immediately. You see when and where problems occurred, which helps with insurance claims or lets you reroute shipments before more damage happens.Â

These sensors provide precise location tracking, too. You know where your components are at any moment. A truck breaks down between ports? A train gets delayed? You find out right away. This visibility lets you decide whether to wait for the original shipment or source components elsewhere to keep production running.Â

Sensor data builds a complete picture of supply chain performance over time. You identify which carriers handle shipments most carefully, which routes consistently cause problems, and which suppliers package products properly for international transport.Â

For a clear visual example of how IoT shipment monitoring works in practice, this logistics breakdown shows real-time tracking, temperature control, and alert systems in action:Â

How IoT Based Shipment Tracking System Works?Â