Why Belt Conveyors Are Essential In Material Handling Systems

The belt conveyor is a billion-dollar industry.

According to Future Market Insights, the global conveyor belt market is valued at USD 4.3 billion in 2025 and is projected to hit USD 6.4 billion by 2035. That represents a significant compound annual growth rate (CAGR) of 4.0% during the forecast period, underscoring the widespread adoption of conveyor systems in key industries.

One common conveyor belt misconception is that these machinery are only resourceful in larger companies. However, belt conveyor systems can fulfill the need for automation for any business, despite its scale. This post looks at the role of belt conveyors in material handling systems.

- Automating Material Handling

The popularity of conveyor belt systems is rooted in their ability to automate material handling. Investing in top-tier belt conveyors minimizes the need for manually hauling products along the factory floor or assembly line. While automation levels vary depending on the conveyor system you choose, most of these equipment can seamlessly transport items for hours without requiring significant human intervention.

2.Streamlining Workflows

Before the advent of modern conveyor belts, transporting essential materials along the production line required positioning several workers at strategic points on the factory floor. Bulky or delicate items would then be relayed from one employee to another. However, the fact that not everyone could keep up uniform pace reduced production efficiency significantly. Conveyor belts have effectively addressed these concerns. By automating material conveyance, the machines streamline workflows while improving overall workplace productivity.

3. Enhancing Speed

Conveyor belts run in the background to ensure items are continuously delivered to wherever they’re required. With these innovative equipment, productivity doesn’t have to suffer on account of employee fatigue or sluggishness. Simply turn the machine on and assign a few operators to load and unload the materials as required.

4.Improving Accuracy

Conveyor belts don’t merely facilitate the movement of items. They discharge that function with remarkable accuracy. Many contemporary belt conveyors utilize advanced technologies like artificial intelligence (AI) and the internet of things (IoT), enabling companies to integrate them with warehouse management systems. For warehouse managers, this can be a significant game-changer in minimizing overstocking and stock-outs.

5.Fostering Standardization

Dispatching non-standardized items can lead to costly product recalls. It may also trigger client exodus, as no consumer wants to pay the same price for inconsistent or incompatible goods. Modern conveyor belts come with calibration mechanisms designed to enhance product consistency. You can implement proper settings for each batch, depending on the weights and volumes of the materials you wish to convey.

6.Minimizing Item Damage

Conveyor belts are ingeniously designed to ensure the safe movement of materials. Noteworthy design specs include impact beds and idlers, which prevent items from falling off the belt. Belt conveyors also feature skirt boards that guard against material spillage. Besides, the pulleys move uniformly to prevent overcrowding. In contrast, manual item handling increases the risks of damage from employee fatigue.

7.Reducing Accidents

Belt conveyors don’t only prevent costly material damages. By reducing manual item handling, these equipment can also minimize workplace accidents due to employee fatigue. Investing in a conveyor belt frees your employees of strenuous tasks like lifting heavy objects or handling hazardous items. The workforce can be redeployed to other critical departments, spurring holistic growth in your business. Moreover, high-end conveyor belts come with advanced features designed to enhance operator safety. Examples include guards, covers, and emergency stop controls.

8.Boosting Hygiene Standards

Upholding proper hygiene at the workplace can minimize frequent employee illnesses, ramping up the overall productivity. It also ensures compliance with relevant Occupational Safety and Health (OSHA) standards. Proper sanitation is particularly critical for companies that deal with sensitive products like consumables, topical, and pharmaceuticals. Conveyor belts provide a hands-off approach to material handling. The equipment reduce direct contact with sensitive goods, minimizing cross-contamination.

9.Managing Energy Consumption

Conveyor belts are power-hungry machinery. So, it may sound counterintuitive to describe them as energy-saving.

However, investing in a conveyor belt can reduce your workplace energy consumption in various ways. First, conveyor systems eliminate the energy required to run product assembly and packaging lines separately. The systems are also low-maintenance compared to other machinery of their caliber, only requiring occasional cleaning. Besides, many conveyor systems today can be set to auto-shut after a predetermined period. This ensures the machine only utilizes energy when they’re operational.

10. Maximizing Floor Space

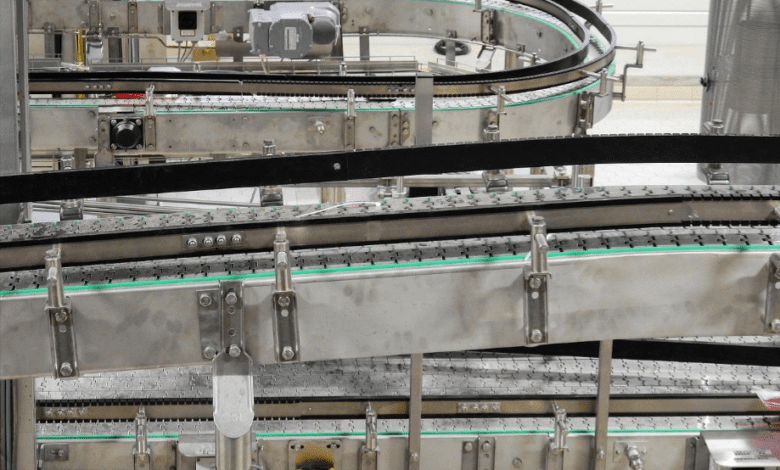

Despite their bulky reputation, conveyor belt systems are incredibly space-saving.Installing a belt conveyor enables you to capitalize on the overhead space. You could also route the machinery over other stationary appliances, streamlining workflows without necessarily relocating bulky factory objects. Thanks to their flexibility, conveyor systems are suitable for different floor layouts.

11. Fostering Environmental Preservation

Conveyor belts automate material handling. They minimize wastage caused when items are damaged along the production or assembly line, making them an eco-friendly investment. Integrating a belt conveyor system into your operations can help ease the strain on our landfills. Also, modern conveyor belts are surprisingly quiet despite their size. The equipment are engineered to address workplace noise pollution.

Final Word

Belt conveyors support automation in material handling systems, improving throughput and streamlining workflows. Integrating conveyor belts into your operations may also enhance employee safety by automating the handling of hazardous or delicate products. Besides, these systems are incredibly versatile and can serve the needs of any business. While there are ethical concerns to navigate – such as the potential for job displacements – the economic benefits of adopting conveyor belts far outweigh any drawbacks.